I-HSS Drills

I-Meiwha Drill Tools inikeza i-HSS Drill kanye ne-Alloy Drill.I-HSS Twist Drill Bit Ground ingeyokubhoboza ngensimbi ngokunemba okukhulu. Ithiphu lephuzu lokuhlukanisa le-bit eliveziwe elingu-135-degree lihlanganisa ukusika okusebenzayo nokubeka maphakathi nendawo okuhle ngaphandle kokuzulazula, iletha ukunemba okuphezulu. Ithiphu ye-split-point futhi isusa noma yisiphi isidingo sokubhoboza kusengaphambili noma ukushayela umshayeli kuze kufike ku-10 mm. Le bithi enembayo eyenziwe nge-HSS (insimbi enesivinini esikhulu) yenza izinga lokumba elisheshayo lifike ku-40% kanye nokucindezela okuphakelayo okufika ku-50% okuphansi kunezingcezu zokubhola ze-HSS ezisezingeni eliphansi ezinemiphetho yeshizolo. Le bit yakhelwe ukubhoboza izimbobo ngensimbi eyingxubevange kanye non-alloyed, insimbi cast, cast iron, sintered iron, cast iron ethambile, izinsimbi non-ayoni kanye namapulasitiki aqinile. Inesistimu ye-cylindrical shank (i-shank elingana nobubanzi be-drill bit) futhi ihloselwe ukusetshenziswa ezindaweni zokubhoboza kanye nezishayeli zokubhoboza.

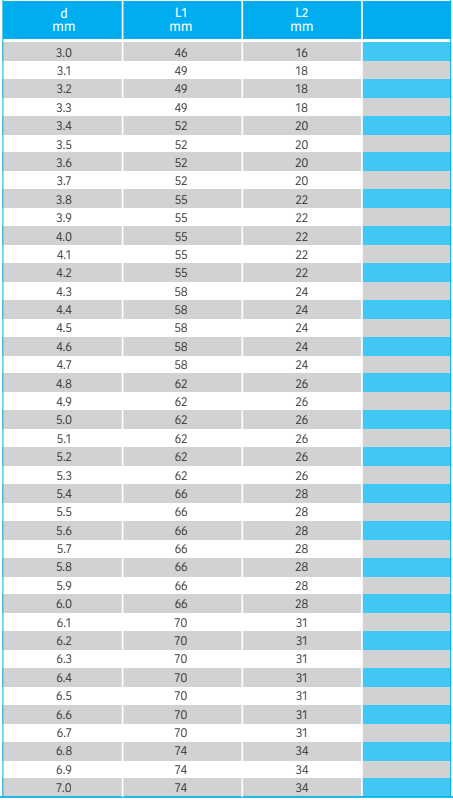

I-HSS Twist Drill Bit Ground yenzelwe i-DIN 1897. Ibhithi yokubhoboza iwuhlobo N (i-angle yomtshingo) enethiphu engu-118-degree kanye nokubekezelela kwediameter engu-h8.

Izinyathelo zokuqapha zokusebenzisa amathuluzi e-carbide enosimende

I-1) I-carbide enosimende iyinto eqinile futhi ephukayo, eshwabene futhi yonakaliswa ngaphansi kwamandla amakhulu noma imiphumela ethile yengcindezi yendawo, futhi inemiphetho ebukhali yokusika.

2) Iningi lama-carbides anosimende ikakhulukazi ama-tungsten ne-cobalt. Izithako zinobuningi obukhulu, ngakho-ke kufanele ziphathwe njengezinto ezinzima ngesikhathi sokuthutha nokugcinwa.

3) I-carbide ehlanganisiwe nensimbi inama-coefficients ahlukene wokunweba okushisayo. Ukuze uvimbele ukugxilwa kwengcindezi ekuqhekekeni, ukunakwa kufanele kukhokhwe ekushiseleni ezingeni lokushisa elifanele.

I-4) Amathuluzi okusika i-Carbide kufanele agcinwe endaweni eyomile, kude nomoya oshisayo.

5) Phakathi nenqubo yokusika amathuluzi e-carbide e-cemented, ama-chips, ama-chips, njll akukwazi ukuvinjelwa. Sicela ulungise izinto ezidingekayo zokuvikela abasebenzi ngaphambi komshini.

6) Uma ukupholisa uketshezi noma imishini yokuqoqa uthuli isetshenziselwa inqubo yokusika, ngokucabangela impilo yesevisi yethuluzi lomshini kanye namathuluzi okusika, sicela usebenzise imishini yokuqoqa uketshezi noma uthuli ngendlela efanele.

7) Sicela uyeke ukusebenzisa ithuluzi elinemifantu ngesikhathi sokucubungula.

I-8) Amathuluzi okusika i-Carbide azoba buthuntu futhi alahlekelwe amandla ngenxa yokusetshenziswa isikhathi eside. Sicela ungabavumeli abangewona ochwepheshe ukuba bacije.

9) Sicela ugcine amathuluzi e-alloy agugile kanye nezingcezwana zamathuluzi we-alloy ngendlela efanele ukuvimbela ukulimala kwabanye.