Isisiki sokugaya esisebenza kahle kakhulu singaqedela umsebenzi wamathuluzi ajwayelekile ngokuphindwe kathathu ngesikhathi esifanayo sibe sinciphisa ukusetshenziswa kwamandla ngo-20%. Lokhu akukhona nje ukunqoba kwezobuchwepheshe, kodwa futhi umthetho wokusinda wokukhiqiza wesimanje.

Ezingqungqutheleni zokusebenzela, umsindo oyingqayizivele wabasiki bensimbi abazungezayo bahlangana nensimbi wakha ingoma eyisisekelo yokukhiqiza yesimanje.

Leli thuluzi elizungezayo elinemiphetho eminingi yokusika lilolonge yonke into kusukela ezingxenyeni ezincane zikamakhalekhukhwini kuya ezakhiweni zezindiza ezinkulu ngokususa izinto ngokunembile endaweni yokusebenza.

Njengoba imboni yokukhiqiza iqhubeka nokuthuthukela ekunembeni okuphezulu nokusebenza kahle okuphezulu, ubuchwepheshe be-milling cutter buyashintsha buthule - i-bionic structure milling cutter eyakhiwe ubuchwepheshe bokuphrinta be-3D ilula ngo-60%, kodwa isikhathi sayo sokuphila siphindwe kabili; ukugqoka kwandisa impilo yethuluzi ngo-200% lapho kucutshungulwa ama-alloys asezingeni eliphezulu.

I. Izinto eziyisisekelo zokusika: incazelo kanye nenani eliyinhloko

I-milling cutter iyithuluzi elizungezayo elinezinyo elilodwa noma ngaphezulu, ngalinye elikhipha ngokulandelana futhi ngezikhathi ezithile isitokwe somsebenzi. Njengethuluzi eliyinhloko ekugayweni, lenza imisebenzi ebalulekile efana nezindiza zomshini, izitebhisi, ama-grooves, ukwakha izindawo ezingaphezulu, nokusika izinto zokusebenza.

Ngokungafani nokusika kwephuzu elilodwa ekuphenduleni, abasiki bokugaya bathuthukisa kakhulu ukusebenza kahle komshini ngokusika ezindaweni eziningi ngesikhathi esisodwa. Ukusebenza kwayo kuthinta ngokuqondile ukunemba kwe-workpiece, ukuphela kwendawo, nokusebenza kahle kokukhiqiza. Emkhakheni we-aerospace, i-milling cutter esebenza kahle kakhulu ingonga kufikela ku-25% wesikhathi sokukhiqiza lapho mshini izingxenye zesakhiwo sendiza.

Ekwenziweni kwezimoto, ukunemba kwamafomu okusika ama-milling anquma ngokuqondile ukunemba okufanele kwezingxenye ezibalulekile zenjini.

Inani eliyinhloko labasiki bokugaya lisekuhlanganiseni kwabo okuphelele kokuguquguquka nokusebenza kahle. Ukusuka ekususeni ngokushesha izinto ezisetshenziswayo ekugwebeni ukuya ekuphathweni kwangaphezulu emishinini emihle, le misebenzi ingaqedelwa ethuluzini lomshini elifanayo ngokushintsha nje izisiki ezihlukene zokugaya, kwehlise kakhulu ukutshalwa kwezimali kwemishini kanye nesikhathi sokushintsha ukukhiqizwa.

II. Umongo womlando: inguquko yezobuchwepheshe yabasiki bokugaya

Umlando wokuthuthuka wabasiki bokugaya ukhombisa izinguquko zobuchwepheshe kuyo yonke imboni yokukhiqiza imishini:

1783: Unjiniyela waseFrance uRené udale umsiki wokuqala wokugaya emhlabeni, evula inkathi entsha yokusika okujikelezayo kwamazinyo.

1868: Insimbi yensimbi ye-Tungsten alloy yaba khona, futhi isivinini sokusika sadlula amamitha angu-8 ngomzuzu okokuqala ngqa.

Ngo-1889: U-Ingersoll wasungula umsiki wokugaya ummbila oguquguqukayo (i-spiral milling cutter), efaka i-blade emzimbeni womsiki we-oki, owaba yisibonelo somsiki wesimanje wokugaya ummbila.

1923: IJalimane yasungula i-carbide enosimende, eyandisa ijubane lokusika ngokuphindwe kabili kunelensimbi enesivinini esikhulu.

Ngo-1969: Ilungelo lobunikazi lobuchwepheshe bokuhlanganisa umhwamuko wamakhemikhali lakhishwa, okwandisa ukuphila kwamathuluzi izikhathi ezingu-1-3.

2025: Abasiki be-Metal 3D-printed bionic milling bathola ukuncishiswa kwesisindo esingu-60% futhi baphinde kabili impilo yabo, beqa imingcele yokusebenza evamile.

Yonke into emisha ezintweni zokwakha nezakhiwo iqhuba ukukhula kwejiyomethri ekusebenzeni kahle kokugaya.

III. Ukuhlaziywa okuphelele kokuhlukaniswa kwe-milling cutter kanye nezimo zohlelo lokusebenza

Ngokomehluko wesakhiwo kanye nomsebenzi, abasiki bokugaya bangahlukaniswa ngezinhlobo ezilandelayo:

| Uhlobo | Izici zesakhiwo | Izimo Ezisebenzayo | Imboni Yezicelo |

| Izigayo zokuqeda | Ukusika imiphetho kukho kokubili isiyingi nobuso bokuphela | I-Groove kanye ne-step surface processing | Ukukhiqiza isikhunta, imishini ejwayelekile |

| Umsiki wokugaya ubuso | Ubuso bokuphela kobubanzi obunama-multi-blade | Indawo enkulu yokugaya enesivinini esikhulu | Ibhulokhi yesilinda yemoto nezingxenye zebhokisi |

| Umsiki wokugaya ohlangothini nobuso | Kunamazinyo nhlangothi zombili kanye nesiyingi | I-Precision groove kanye nokucubungula izinyathelo | I-hydraulic valve block, isitimela somhlahlandlela |

| Izigayo zokuphela kwebhola | I-Hemispherical cutting end | 3D surface processing | Ama-Aviation blades, i-mold cavities |

| Umsiki wokugaya ummbila | Ukuhlelwa kwe-spiral yokufaka, isikhala esikhulu se-chip | Ukugaya ihlombe elinzima, ukugoba okujulile | Izingxenye zesakhiwo se-Aerospace |

| I-saw blade milling cutter | Izingcezu ezizacile ezinamazinyo amaningi kanye nama-engeli achezukile ezinhlangothini zombili | Ukujula nokuhlukana okujulile | Izingcezu ezizacile ezinamazinyo amaningi kanye nama-engeli achezukile ezinhlangothini zombili |

Uhlobo lwesakhiwo lunquma ukonga nokusebenza

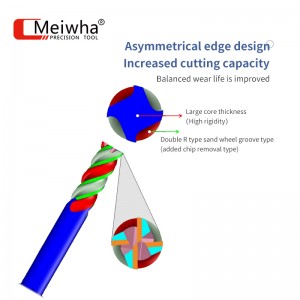

Okupheleleumsiki wokugaya: Umzimba wokusika kanye namazinyo akheke ngokuhlangene, anokuqina okuhle, afanele umshini wokunemba wobubanzi obuncane

Izisiki zokugaya ezitholakala kunkomba: ukufakwa esikhundleni okungabizi kakhulu kunethuluzi lonke, elilungele ukugoqa.

Umsiki wokugaya oshiselwe: ithiphu le-carbide elishiselwe emzimbeni wensimbi, izikhathi zokugaya kodwa ezinomkhawulo

Isakhiwo se-bionic esiphrintiwe se-3D: idizayini yangaphakathi yekhekheba lezinyosi, ukunciphisa isisindo ngo-60%, ukumelana nokudlidliza okuthuthukisiwe

IV. Umhlahlandlela Wokukhetha Wesayensi: Amapharamitha Abalulekile Ukufanisa Izidingo Zokucubungula

Ukukhetha i-milling cutter kufana nodokotela echaza incwadi kadokotela - kufanele unikeze umuthi ofanele ngesimo esifanele. Okulandelayo yizici zobuchwepheshe ezibalulekile zokukhetha:

1. Ukumatanisa kobubanzi

Ukujula kokusika ≤ 1/2 ububanzi bethuluzi ukuze kugwenywe ukushisa ngokweqile nokuguqulwa. Lapho ucubungula izingxenye ze-alloy aluminium ezinodonga oluncane, kuhle ukusebenzisa isigayo sokuphela kobubanzi obuncane ukunciphisa amandla okusika.

2. Ubude be-blade nenani lama-blade

Ukujula kokusika ≤ 2/3 yobude be-blade; ukuze uqine, khetha ama-blade angu-4 noma ngaphansi ukuze uqinisekise isikhala se-chip, futhi ukuze uqedele, khetha ama-6-8 ama-blade ukuze uthuthukise ikhwalithi yendawo.

3. Ukuvela kwezinto zamathuluzi

Insimbi enesivinini esikhulu: ukuqina okuphezulu, ifanele ukusika okuphazamisekile

I-carbide enosimende: ukukhetha okujwayelekile, ubulukhuni obulinganiselayo nokuqina

I-Ceramics/PCBN: Ukunemba kwemishini yezinto eziqinile, ukukhetha kokuqala kwensimbi eqinile

I-HIPIMS coating: I-PVD entsha yokumboza inciphisa unqenqema olwakhiwe futhi inwebe impilo ngo-200%

4. Ukwenziwa ngcono kwepharamitha yeJiyomethri

I-engeli ye-Helix: Uma ucubungula insimbi engagqwali, khetha i-engeli encane ye-helix (15°) ukuze ukhulise amandla onqenqema.

I-engeli yethiphu: Ngezinto eziqinile, khetha i-engeli enkulu (>90°) ukuze uthuthukise ukusekela

Onjiniyela banamuhla basabhekene nenselelo yombuzo ongaphelelwa yisikhathi: indlela yokwenza ukusika kwensimbi kube bushelelezi njengamanzi agelezayo. Impendulo itholakala ezinhlansini zokuhlakanipha ezishayisana phakathi kwensingo ephothayo nobuhlakani.

[Thintana nathi ukuze uthole izixazululo zokusika nokugaya]

Isikhathi sokuthumela: Aug-17-2025