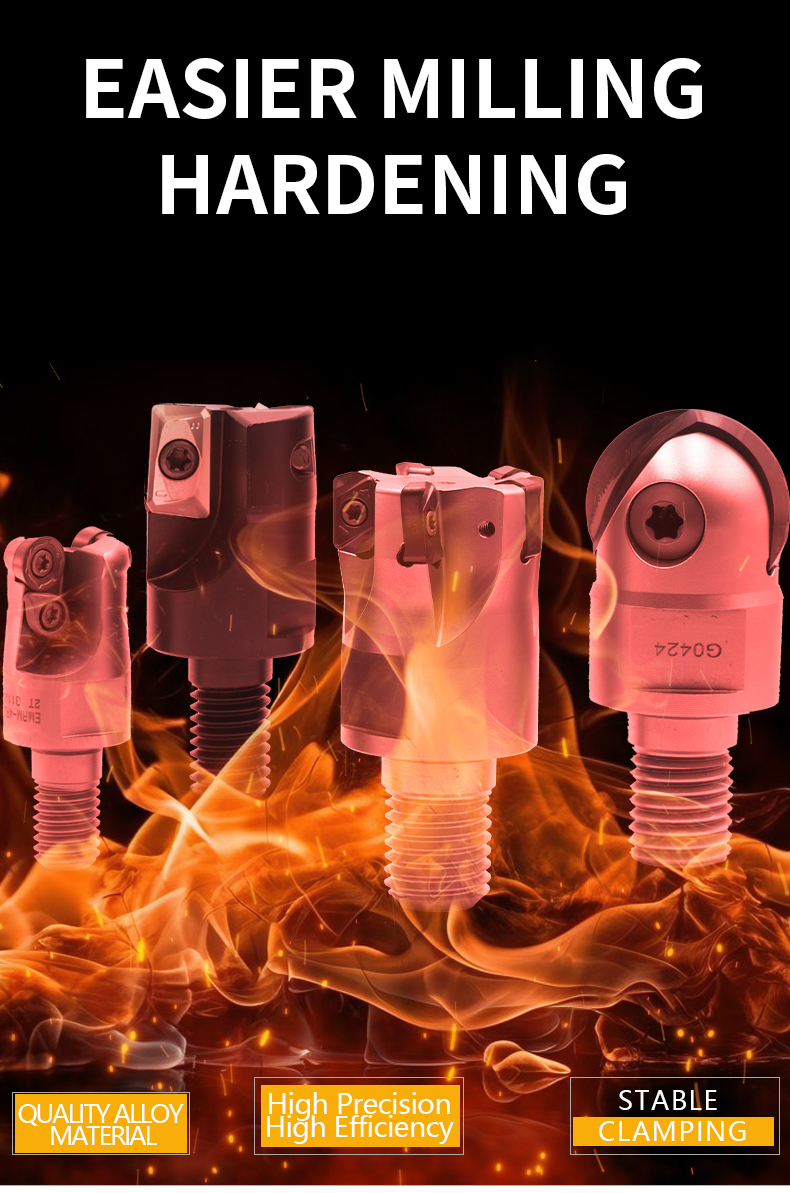

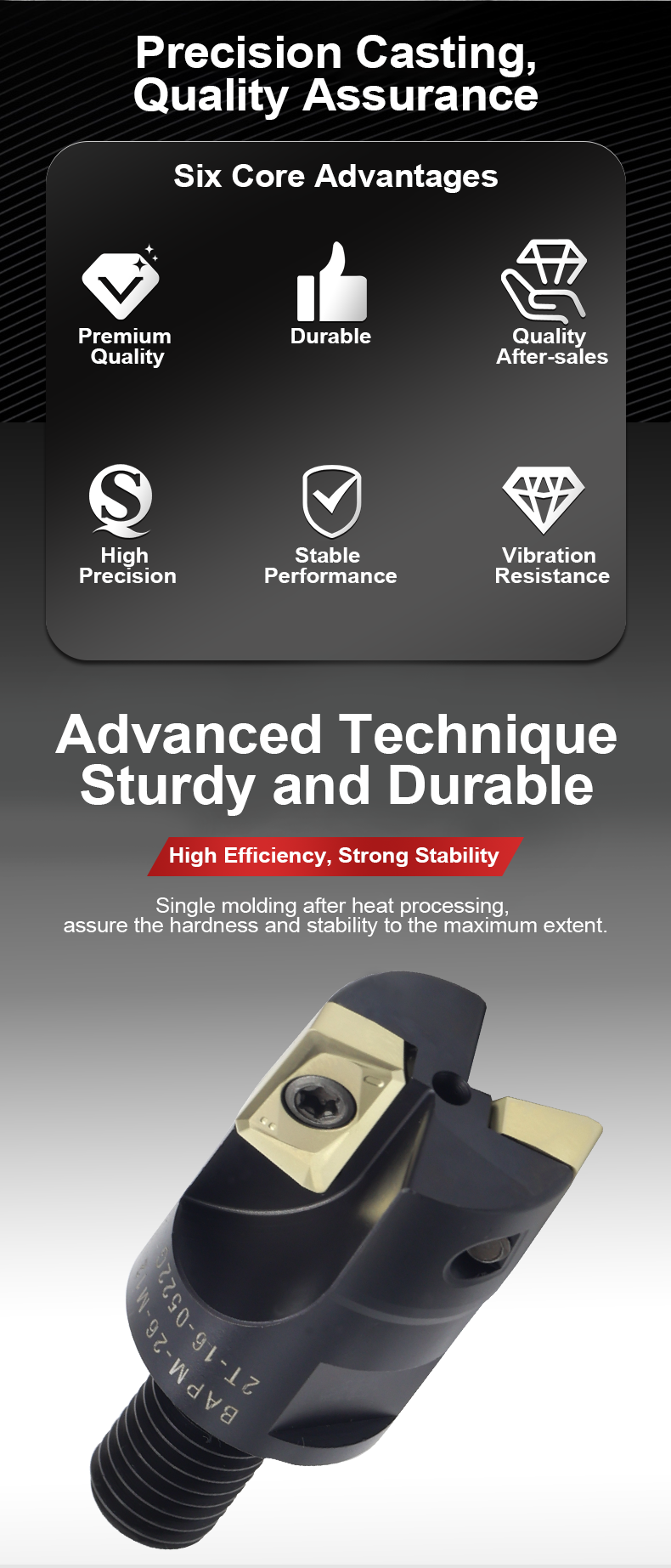

I-Shell Mill Cutter

Lapho Usebenzisa I-Shell Mill?

I-Shell Mill ivame ukusetshenziswa ezimeni ezilandelayo:

I-Surface Milling Enkulu:Izigayo zegobolondoabe namadiamitha amakhulu, okuwenza alungele ukugaya izindawo ezinkulu ngokushesha.

Ukukhiqiza Okuphezulu: Idizayini yazo ivumela ukufakwa okwengeziwe namazinga aphezulu okuphakelayo, ukuthuthukisa ukukhiqiza.

I-Versatility: I-tooling ingashintshwa kalula, yenziweizigayo zegobolondoeguquguqukayo ngezinto ezahlukahlukene kanye nokuqedwa.

I-Surface Finish Engcono: Inani elandiwe lemiphetho yokusika livame ukuholela endaweni eqediwe ebushelelezi.

Ukusebenza Kwezindleko: Naphezu kwezindleko zokuqala eziphezulu, ikhono lokushintsha okufakiwe ngakunye kunethuluzi lonke lingonga izindleko ngokuhamba kwesikhathi.

Shell Mill Izinzuzo

I-Versatility - Izigayo zeShell zingenza cishe noma yiluphi uhlobo lwemisebenzi yokugaya noma ye-slot. Ukuguquguquka kwabo kuvumela ithuluzi elilodwa ukuthi ligaye izindawo eziyisicaba, amahlombe, izikhala, namaphrofayili. Lokhu kunganciphisa inani lamathuluzi adingekayo esitolo.

Isilinganiso Sokususwa Kwezinto Ezibalulekile - Indawo enkulu yokusika yamagobolondo asho ukuthi angakwazi ukususa izinto ngokushesha kunezigayo zokugcina. Amazinga azo aphezulu okukhipha insimbi awenza afaneleke kahle ukusikeka okumahhadlahhadla nokusetshenziswa kwemishini esindayo.

Ukusika Okuzinzile - Imiphetho ebanzi yokusika kanye nokuqina kwemizimba ye-shell mill inikeza ukusika okuzinzile, ngisho nokujula okujulile kwe-axial kokusika. Izigayo zamagobolondo zingathatha ukusikeka okukhulu ngaphandle kokuchezuka noma ukuxoxa.

Ukulawula I-Chip - Amacici ku-shell mill cutters ahlinzeka ngokukhipha okuphumelelayo kwe-chip ngisho nalapho egaya imigodi ejulile noma amaphakethe. Lokhu kuzivumela ukuthi zihlanze isigayo esinethuba elincane lokusika kabusha i-chip.

Ububi beIsigayo seShell:

Isicelo Esinomkhawulo: Njengezigayo zobuso, izigayo zamagobolondo zisetshenziselwa ukugaya ubuso futhi kungenzeka zingalungeli imisebenzi yokugaya enemininingwane noma eyinkimbinkimbi.

Izindleko: Izigayo zeShell nazo zingaba nezindleko eziphakeme zokuqala ngenxa yobukhulu nobunkimbinkimbi bazo.

Idinga I-Arbor: Izigayo ze-Shell zidinga indawo yokubeka ukuze ifakwe, enezela kuzo zonke izindleko kanye nesikhathi sokusetha.

Izinto Zokukhetha Ithuluzi Le-Shell Mill

I-Cutter Material - Izigayo zegobolondo ze-Carbide zinikeza ukumelana okungcono kakhulu kokugqokwa kwezinto eziningi. Insimbi enesivinini esiphezulu ingasetshenziswa futhi kodwa inqunyelwe ekunciphiseni izinto zokuqina.

Inombolo Yamazinyo - Amazinyo engeziwe azohlinzeka ngokuqeda okuhle kodwa amanani okuphakelayo aphansi. Amazinyo ama-4-6 ajwayelekile ukuthi aqine kanti amazinyo angu-7+ asetshenziselwa ukuqeda kancane/ukuqeda.

I-Helix Angle - I-engeli ye-helix ephansi (ama-degree angu-15-30) iyanconywa ukuze kube nzima ukwenza umshini kanye nokusikeka okuphazamisekile. Ama-engeli e-helix aphezulu (amadigri angu-35-45) enza kangcono ekugayeni okuvamile kwensimbi ne-aluminium.

Ukubalwa Kwe-Flute - Izigayo zeShell ezinemitshingo eyengeziwe zivumela amazinga aphezulu okuphakelayo kodwa zidela isikhala sokuphuma kwe-chip. 4-5 imitshingo ivame kakhulu.

I-Insets vs Solid Carbide - Izinqamuli zamazinyo ezifakiwe zivumela ukukhonjwa kokufakiwe okusika okushintshwayo. Amathuluzi e-Carbide aqinile adinga ukugaywa/ukulola uma kugqokwe.